Jinsanyang Company is a leading enterprise in the production of organic glass products, with considerable experience, technology, and equipment. The organic glass product workshop can undertake the business of organic glass outsourcing, batch processing, and manufacturing to external parties, and can process and produce according to user drawings or samples. Our product philosophy is clear, timely handover, advanced craftsmanship, complete equipment, exquisite, meticulous, beautiful, and practical. We welcome customers to visit and cooperate with us.

Ion exchange devices are mainly used for water treatment and purification, removing various impurities such as ions and collagen from raw water. In recent years, with the development of science, this equipment has continuously expanded its application fields, such as the purification of wine juice in the wine industry, biotechnology chemical preparations, and the purification of various liquids in colleges, universities, scientific academies, and laboratories.

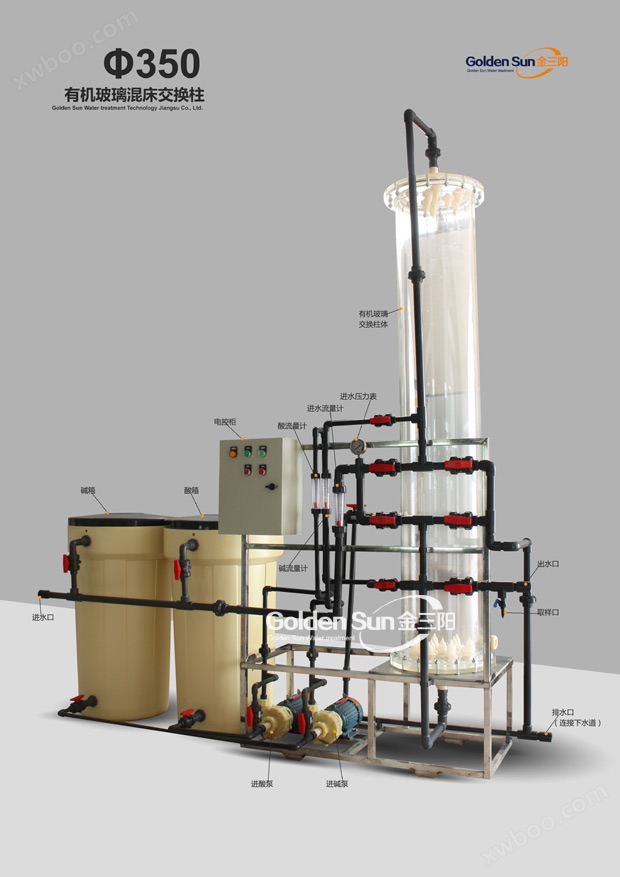

The main component of ion exchange equipment is the exchange column, which is filled with filter media, resin, quartz sand, and various different fillers. Users can choose according to their own needs (our unit does not provide fillers in the column, and can purchase them on behalf of the manufacturer specified by the user). The exchange column is designed to be fixed on a fixed frame and connected with ABS pipelines, with the following functions: liquid inlet, liquid outlet, exhaust, and cleaning. The working principle is mainly achieved through the control of valves to accomplish the above functions.

The ion exchanger can be used as a single column or in series with multiple columns. Multiple columns connected in series, with multi-level purification function, greatly improving the purification effect. The most widely used type of heat exchanger in China is the multi column series connection type.

Our unit uses organic glass reinforced composite materials to manufacture three column heat exchangers and multi column series heat exchangers (see drawings) based on market demand. They are mainly used for water purification (users can also use them for other fluid purification), and have the characteristics of high pressure resistance and strong strength.

Main technical indicators and parameters:

1、 Overall dimensions 2. Exchange column dimensions, stainless steel fixing frame 3. ABS pipeline specifications 4. Positive and negative resin filling amount and water production volume 5. Water quality indicators for effluent

For irregular equipment, it can be formulated through negotiation between Party A and Party B.

|

model |

specifications | Work pressure (Mpa) | Water production rate (T/H) |

| JSY-030 | 300X2000 | 0.3 | 1.0-1.5 |

| JSY-035 | 350x2000 | 0.3 | 1.5x2.0 |

| JSY-040 | 400X2000 | 0.3 | 2-2.5 |

| JSY-050 | 500X2000 | 0.3 | 2.5-3.0 |

| JSY-060 | 600X2000 | 0.25 | 3.0-5.0 |

| JSY-080 | 800x1500 | 0.2 | 5.0-6.0 |

Dimensions of each part of the organic glass ion exchange column and ABS pipeline diameter

|

∮ | H1 | H2 | H3 | H4 | L1 | L2 | L3 | ∮DN | ||

| JD-015×1000 | 150 | 1600 | 1350 | 400 | 1000 | 1000 | 330 | 230 | 15 | ||

| JD-020×1500 | 200 | 2150 | 1350 | 400 | 1500 | 1200 | 360 | 270 | 15 | ||

| JD-026×2000 | 260 | 2600 | 1400 | 400 | 2000 | 1400 | 460 | 360 | 20 | ||

| JD-030×2000 | 300 | 2600 | 1400 | 400 | 2000 | 1500 | 510 | 410 | 25 | ||

| JD-040×2000 | 400 | 2650 | 1400 | 400 | 2000 | 1900 | 640 | 530 | 25 | ||

| JD-050×2000 | 500 | 2650 | 1400 | 400 | 2000 | 2250 | 750 | 640 | 32 | ||

| JD-060×2000 | 600 | 2850 | 1400 | 400 | 2000 | 2600 | 910 | 770 | 40 |

Configuration instructions for organic glass ion exchange columns

| Component Name | quantity | material | Component Name | quantity |

| exchange column | 3 | organic glass | conductance | 1 |

| Fixing frame | 1 | stainless steel | filter | 1 |

| Acid alkali pump | 1 | plastics | pipeline connection | full set |

| Acid base tank | 1 | PVC |

Drainage cap |

|

| pressure gauge | a | Water injector | ||

| flowmeter | 1 |